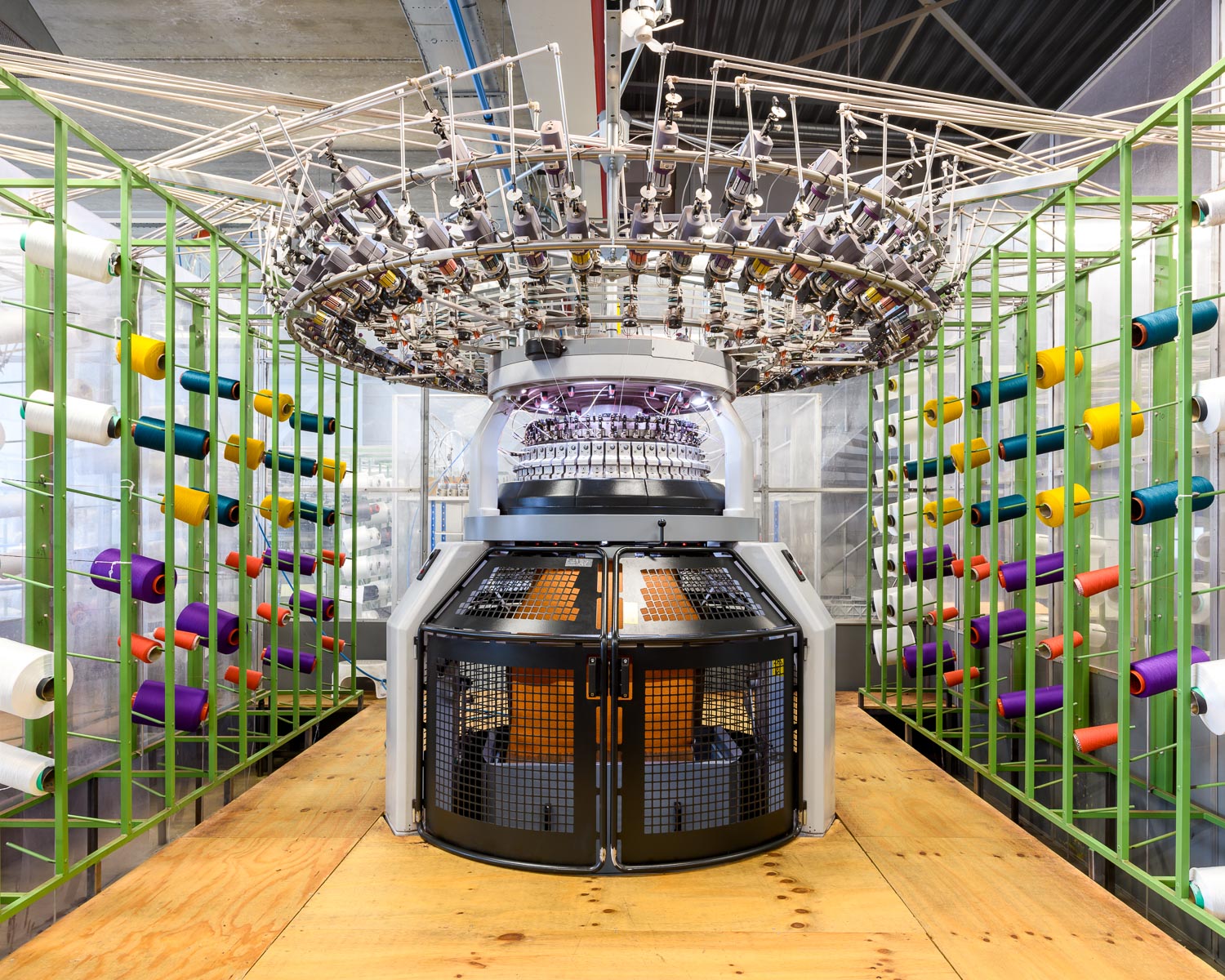

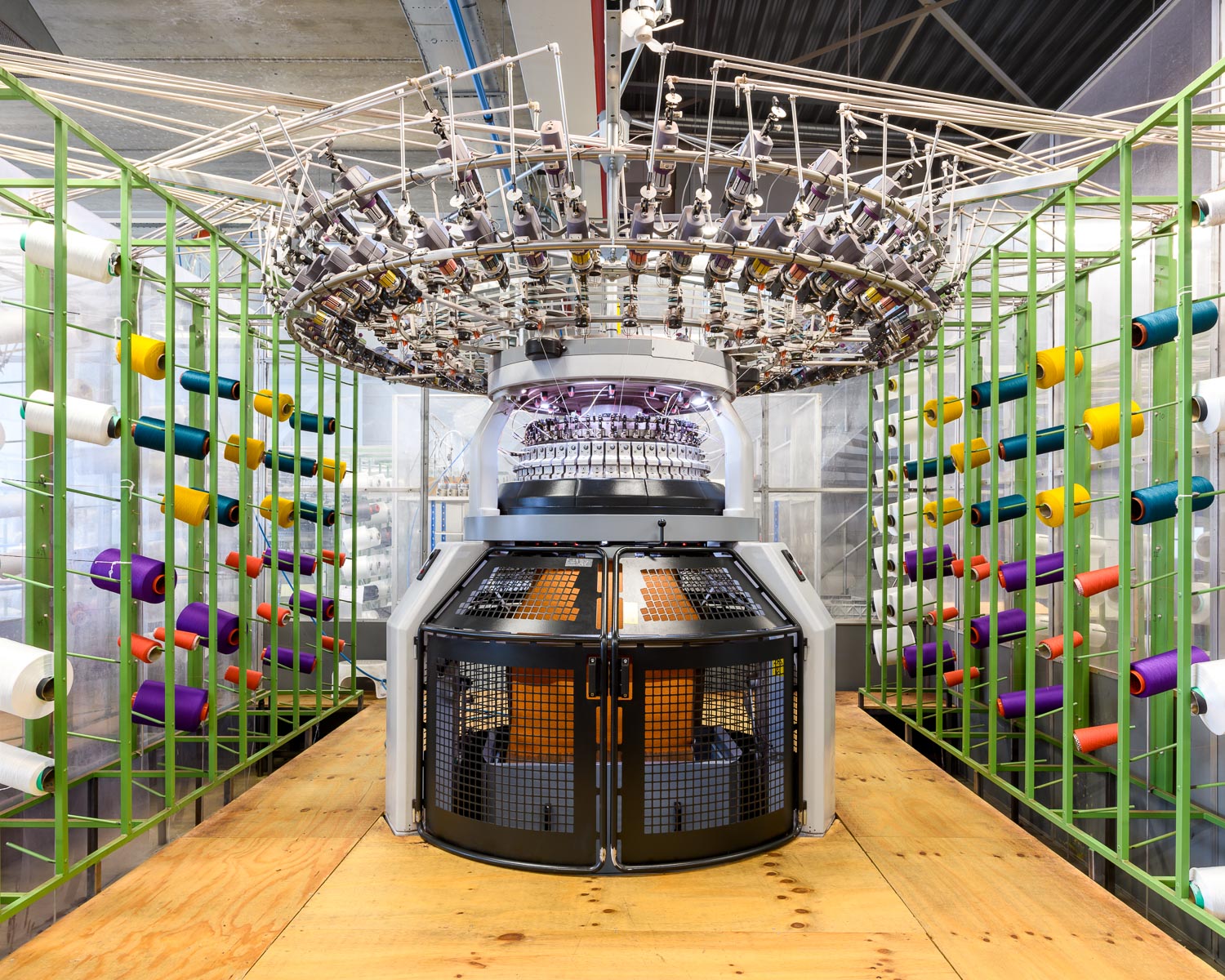

"Unlike many apparel manufacturers, our factory has in-house knitting machines with a daily capacity of 3000 kg."

We produce textiles with deep, durable hues that hold up well against numerous washings using cutting-edge dyeing methods.

Our cutting method lays the basis for well-fitting, green clothing by ensuring precise cuts for the best fit and the least amount of fabric

We promise reliable, superior seams that improve each garment's appearance and longevity.

Below, we proudly highlight our in house embroidery facility: • Number of Machines: 3 x 20 heads

We also have a printing facility in-house with the below detail: • HTL prints – 1000 pcs • High density print – 1000 pcs

Using specialized packaging that fits the brand ensures each product is safely packed and delivery-ready.

Climate-controlled storage ensures product safety and timely delivery for smooth supply chain management.

We prioritize eco-friendly practices and waste reduction to minimize environmental impact. .